Top tips to creating an effective fashion critical path

In business it’s rare for everything to go perfectly to plan. Nowhere is this truer than when you’re bringing your ideas to life in a fashion collection. From sourcing materials to developing tech packs and working through the sampling process, coordinating all your suppliers and stakeholders to the same timeline can be a huge headache. Developing an effective critical path will help you to meet your deadlines and overcome any challenges along the way.

What is a fashion critical path?

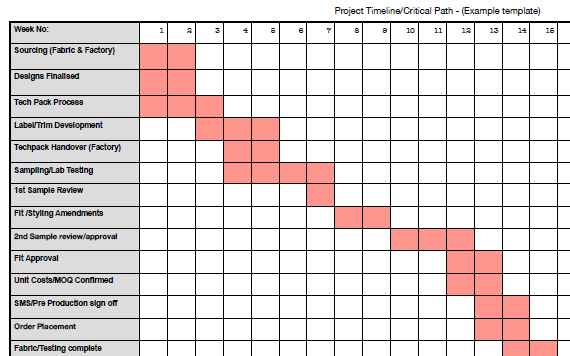

A fashion critical path is a production plan that includes all the steps required to fulfil the delivery of your fashion items or collection. Though the template used may be similar, the specific elements in each critical path will change depending on the particular requirements and timeline for each collection.

The length and details included in each fashion critical path will also vary from project to project, though they can run anywhere from 6 to 18 months and include the key steps in product development, sourcing, sampling and production. This can be developed alongside suppliers and stakeholders at the beginning of a project and distributed to ensure everyone understands each step and milestone.

What are the benefits of a fashion critical path?

There are lots of benefits to using an effective critical path, including:

Being able to adjust it to the needs of the specific project - either with adding/updating key tasks, or assigning planned and actual dates to a particular stage.

Establishing milestones that can be shared with suppliers and stakeholders to ensure they have a full picture and are accountable for meeting them.

Real time visibility on whether an item or collection is likely to be delivered on time or not.

Proving insight in advance of potential challenges so the product development or production process isn’t stopped in its tracks.

Ensuring that no critical stages such as fit approval, bulk fabric ordering etc are missed or rushed

In short, having a reliable critical path that you, your suppliers and stakeholders can follow, means you have a set process with established milestones for everyone to follow and work to resulting in a better quality product big delivered on time.

Tips for creating a good fashion critical path:

To ensure this planning tool is created effectively, keep the following tips in mind.

#1 Know your launch dates

It’s important to allow a sufficient and realistic amount of time for the product to actually be designed, made and shipped in time for your planned launch. Doing this will ensure you don’t miss the final launch date and waste the money spent on any packaging, marketing and events or disappoint any retailers you’ve committed to.

The last milestone on the critical path should be set just before your launch. However, you may create an extra section of the critical path that will set out the different stages you need to meet up to the launch, e.g. any marketing planning, website build or eCommerce, that can run after or in tangent with the production critical path.

#2 Establish manufacturing locations

You may have selected a particular region to manufacture in based on the particular fabrics, quality levels and price points you want for your product or collection. However, different regions will have varying lead times on the garments they produce as well as in the type of products they make.

For example, Europe can have lead times of six to eight weeks for production processes, whereas China will be around 12 weeks depending on the fabric types and availability. Therefore, it’s important to bear these differences in mind when building out your critical path.

#3 Give extra time to product development

Each manufacturer will interpret your designs and tech packs in different ways. Therefore, you don’t just need to build in enough time to find the right manufacturer for your needs, but plenty of space for the sampling and review process. It’s also key that these timelines are shared with any stakeholders who need to be part of the review process so they’re aware of the dates in advance and can put time aside.

Also, the design, fabric, quality and fit are all being developed, meaning you may need several sampling stages depending on the complexity of each item and the number of products in each collection. It will also take time for any samples from the manufacturer to be delivered, which needs to be accounted for in your planning.

#4 Back it up with accurate tech packs

By building a thorough and detailed tech pack alongside each stage of the critical path process, you will be able to keep track of each stage of development more effectively. By keeping any product details or communication in one place, the product development process will run a lot more smoothly, particularly when transitioning into the production stage. In short, having both a detailed, accurate tech pack and critical path will ensure there are fewer problems with the aesthetics or quality of a product and ensure it arrives on time.

#5 Ask your manufacturer for lead times

Be aware that any delay to certain tasks on your critical path (even by a day) could impact the final delivery date of your product. For example, if your trims have not arrived at the factory by the day production needs to start, the factory will bump your order to accommodate another client, meaning you’ll need to renegotiate a production slot and delivery date.

To mitigate this, ask each supplier and manufacturer for their lead times and leave a bit of buffer to make sure one missed day doesn’t turn into a two-week delay in your delivery times.

#6 Define each key milestone

Missing a specific step in the process has the potential to set your final delivery date back by a week or more. Taking the time to carefully consider each stage at the beginning and detail each of them with as much information as possible will ensure you or your supplier don’t get caught out further down the line.

Alongside the stages, be aware that there are many different dates to hit, from the concept stage to delivery. Some of these dates may run consecutively and others will fall parallel to each other, so make sure you allow enough time for each task and add buffers of a day or more where appropriate. Your manufacturer will be able to guide you on certain aspects if necessary.

#7 Monitor your critical path regularly

As well as sending out the critical path document to all your suppliers and stakeholders, ensure you have a scheduled weekly call with your manufacturer to talk through the stages. This keeps communication running smoothly and allows any potential problems to be highlighted or resolved before they become an issue so no one fails on the commitments set by the critical path timeline.

#8 Update regularly with ‘actual dates’

Initially, your critical path will only identify which week each stage will be completed. Your document will start off with ‘planned’ dates which should be a constant and are there to guide you through the process, but putting in actual dates as soon as possible will help you to demonstrate actual progress.

As more detail is added and manufacturers’ lead times are finalised, it’s important to put actual deadlines and dates against each stage. This allows you to keep a closer track of what's happening, what the upcoming stages are and help you work back accurately from your final delivery date.

#9 Keep geo-political contingencies in mind

It’s important to note that some manufacturers’ lead times have not yet recovered to pre-pandemic levels, so you need to build in extra time as a contingency for this. There are also impacts as a result of various ongoing wars, riots in Bangladesh, oil price instability, among other things.

#10 Allow for shipping times

When building out the shipping and distribution stages of the critical path, refer to the transport method that will be used and the distance between a manufacturer’s location and the products’ final destination. Creating the critical path will also give you an idea of when shipping is likely to be needed so you can book it in advance and save on the cost.

For example, if the product is being delivered by road to the UK, it will take one to two weeks from Turkey. Sea freight from the Far East (China, India, Sri Lanka, Bangladesh, etc.) can take six to eight weeks. Air freight can be much quicker, but should only be used as a last resort due to its environmental impact.

Need help finding your way?

Whether you need help building a bespoke fashion critical path or wonder how best to define each stage, our team can help. With plenty of experience in planning and working on a whole range of projects, email us at enquiries@fashiondelivered.com to find out more.

Or click in the button below to arrange a no obligation chat.